The Complete Guide to AR-15 Barrels

Posted by Gun Builders Depot on Jul 3rd 2019

The barrel is arguably the most important part of your AR-15. It determines what types of rounds you can shoot, how accurate you can get, and how far you can reach out and touch targets. Picking the perfect barrel can make or break any AR build. Today, we're going to go over everything with a complete guide to AR-15 barrels!

We'll explain twist rate, barrel length and velocity, how barrels are made, and with what materials. We'll even get into barrel profiles, rifling, and barrel treatments. It's A to Z today, so let's get started.

This article is a part of our Full Parts Guide to Building an AR-15.

AR-15 Barrels: Twist Rate Explained

Twist rate's arguably the most important factor in your AR-15's barrel. Twist rate determines how often the round you fire completes a full rotation in a given distance. More importantly, this dictates how accurate your rifle or pistol is. Think of it like throwing a good ole' pig-skin. How many times does the ball spin before it hits its mark?

Twist rate in a barrel is the same concept. You've probably seen numbers and figures spelling out twist rates like "1:7"or "1-in-8 twist". The first number ("1") means your bullet rotated one full rotation. The second number ("7" and "8") mean that one rotation occurred in either seven or eight inches. Twist rates will almost always be expressed as "1:'number'". Pretty simple, right?

How twist rate affects accuracy

When we throw a football, we impart spin on it to stabilize it and to help it go where we aim. These same physics go to work when you impart spin on a bullet using the rifling in your barrel. The real question is, how much spin should you impart on your rounds?

There ain't no "one size fits all"

Unfortunately, there is no "universal" twist rate that works for every single cartridge on the market. Twist rate needs to match the characteristics of the bullet being fired. If your twist rate's too low, there won't be enough spin imparted on the round and it will fail to stabilize in the air.

The twist rate Goldilocks

When a round isn't stabilized, it usually tumbles end-over-end and hits its target in what is commonly called a "keyhole" shot. It's a little cartoon-ish, but a keyhole shot will create a bullet hole in the shape of the actual bullet itself. But if twist rate's too high, it'll put too much spin on your round. Over-spinning a round can still cause keyholing. It can even be dangerous. Excessive spin can cause a round to fragment and destroy itself, sending debris and bits of lead or jacket flying off where you don't want it to go.

When picking the right twist rate, the goal is to find a barrel that'll give your AR's rounds the flattest, straightest trajectory possible by spinning it just the right amount. So, how do we figure that out?

Picking the right twist rate

Many shooters, even professionals, will casually tell you that picking the perfect twist rate hinges on the weight, or grain count, of the bullets you're shooting. Bob at the gun range, with his custom black rifles, will stand fast by his belief that a light, 55-grain bullet NEEDS a 1:7 twist rate. Or that heavier, 77-grain bullets just absolutely must have a 1:9 twist rate, no matter what.

It's not about the weight

While Bob might be right, his reasoning isn't completely correct. Weight plays some role in determining twist rate, but it's actually more of a correlation. Ultimately, picking the right twist rate comes down to the length of your bullets. The only reason weight comes into the conversation frequently is because, well, longer bullets tend to weigh more!

The Golden Rule of twist rate

Ready for it? The longer the bullet (and yes, generally, the heavier), the "faster" or more extreme the twist rate you'll need to stabilize that round in flight. Since we're talking about AR-15s, let's focus on what the optimal twist rate is for 5.56 and .223, first:

The best twist rate for 5.56/.223![]()

Let's keep it simple: If you're building or shooting a 5.56/.223 gun, you want a 1:7 or 1:8 twist rate. The AR-15/M16 originally used a 1:14 twist rate to accommodate the military's short, light 55-grain spitzer rounds. To squeeze out more stability at greater distances, the military later converted to a 1:12 twist rate. Eventually, the military also decided they need more penetration and power, so they upped the powder, and velocity in their cartridges and started using longer, heavier bullets. Fast-forward to modern day, and the U.S. Military almost exclusively uses 62-grain or 77-grain 5.56 loads that require a 1:7 twist rate. These are also the most common cartridges (besides 55-grains) used by civilian shooters and AR-15 owners across the country.

Optimal twist rate for 300 Blackout![]()

300 Blackout was designed to be fired in a subsonic, suppressed configuration while affording the ability to shoot as supersonic rounds, too. This is a difficult round to pick an optimal twist rate for, but most shooters agree that a 1:8 twist rate is best all around. Subsonic 300 Blackout rounds typically weigh 200 to 220 grains and optimal velocity is achieved in a shorter barrel (around 9"), requiring a faster rate of rotation to stabilize. If you plan on never shooting subsonic loads and prefer shooting lighter, shorter rounds at distance, a 1:10 to 1:12 twist rate is preferred.

Best twist rate for .308![]()

.308 Winchester is a well-established, popular round. It's made its mark in the AR world, being featured in loads of AR-10 clone and LR-308 builds. Most .308 rounds weigh in at 175 or 168 grains (or even less), and its this weight and bullet length that requires .308 AR to have a 1:10 twist rate for optimal performance. You can pick up heavier, longer .308 loads (200-grain+), but overall velocity and thus range and hit probability will suffer.

AR-15 Barrel Lengths: Which is Best?

Barrel length has been a long-debated topic, especially in the black rifle community. Ask most folks about barrel length on any gun and they'll say, "The longer the better." Unfortunately, they'd be wrong. Yes, the M16 originally sported a 20" barrel and newer M4 rifles (and nearly all AR-15s) use shorter 16" or 14.5" barrels to make handling and maneuverability easier. But those shorter barrels are just as accurate and capable as Eugene Stoner's original 20" design.

How barrel length affects accuracy

Technically, barrel length doesn't affect accuracy at all. It affects velocity. When you fire a round in your AR-15, the primer ignites. Excess gas builds up, forcing the bullet down the barrel. The longer your barrel, the longer those gasses remain trapped behind that bullet. The longer gas is trapped, the more time it has to build up that bullet's velocity.

It's all about speed

The only purpose a barrel's length serves is to get your round up to its optimal velocity, so the rifling inside the barrel can spin it appropriately and get it moving in a relatively flat trajectory. That's it. It's the combination of velocity (from the gas) and stabilization (from the rifling) that yields real accuracy and distance. Just because a barrel's longer does not mean it will make your round more accurate.

Length, velocity, and diminishing returns

Picking the right barrel length comes down to figuring out diminishing returns. As barrel length increases, velocity increases. This increase in velocity is logarithmic, meaning that the longer the barrel gets, the less effect it has on adding more velocity. Think of it like a sportscar: It only takes a few extra horsepower to get from 110 to 130 MPH. It'll take a Helluva lot of extra horsepower to get from 250 MPH to 275 MPH. There is a point where adding more barrel (more horsepower) becomes useless.

Finding a balance

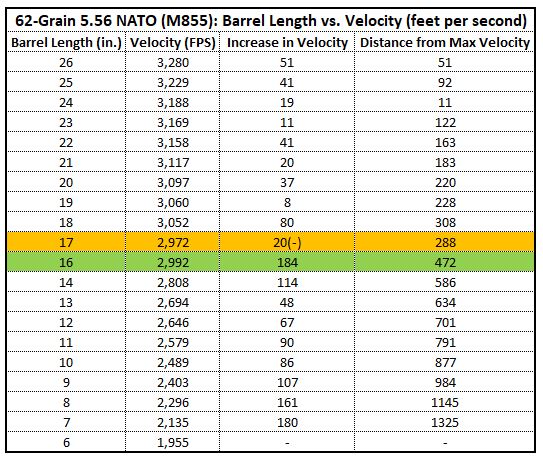

Basically, you need to figure out the point at which adding more barrel yields little to no extra velocity. Going from a 10" to a 16" barrel might increase velocity by 15%. Going from a 16" to a 20" barrel may increase velocity by just 3%. You also need to consider the optimal velocity of the round you're shooting. In the example below, we've captured the barrel length and velocity data for the common M855, 62-grain 5.56 NATO cartridge:

As we increase our barrel length from a measly 6" up to 14", we see increases in velocity. There are some diminishing returns as barrel length increases. But suddenly, we get to 16" and some weird stuff happens:

Remember Goldilocks?

Our increase in velocity jumps by 184 FPS, and when we go up one more inch (to 17"), we actually lose velocity! As we continue adding length to our barrel (from 17" up to 26"), we start to see more of those diminishing returns. Eventually, we gain just 11 and 19 FPS per extra inch of barrel. Small potatoes.

For the typical black rifle chambered in 5.56 or .223, a 16" barrel is the sweet spot. This data backs that up. The same rules apply to any AR-platform rifle or pistol, there is a Goldilocks zone that'll give optimal velocity with the shortest possible barrel length.

Barrel Rifling Types and Methods

Most AR barrels are cold- or hot-hammer forged, cut, or button-rifled. These processes are so modernized that the resulting barrel will afford most shooters more accuracy than they can handle. Nonetheless, let's quickly look at these three rifling and manufacturing processes for the sake of knowledge:

Cold-hammer forged barrel

Cold-hammer forged (CHF) barrels are among the most popular types of barrels found on the AR-15 market today. Cold-hammer forging a barrel involves taking a barrel blank and forcing a mandrel with the reverse imprint of the barrel's rifling into the blank. Hammers then beat the barrel blank around the mandrel in a process called rotary forging. This will give the barrel its final shape and forge the rifling's lands and grooves inside. The finished barrel is then squeezed up and off the mandrel. CHF barrels are incredibly hard and rugged, promising long barrel life and high performance with rapid-fire.

Cut-rifled barrel

Cut rifling is an old-school method of making a barrel. This method takes time, but it produces the most accurate rifling. As the name implies, cut rifling is formed by using a single cutter to carve out the rifling lands and grooves, one at a time. Each cutting pass only removes about one-ten-thousandth of an inch. Modern cut rifling a barrel takes at least one hour or more. The resulting barrel will be match-grade and offer sub-MOA accuracy.

Button-rifled barrel

Button-rifled barrels are manufactured under extreme pressure like CHF barrels, but in a different way. Button-rifled barrels also use a mandrel to carve out the rifling's lands and grooves. Unlike cold-hammer forging, a button-rifled barrel is finished by literally ramming the mandrel through the barrel in one pass, using a large hydraulic press.

Which barrel rifling method is best?

It comes down to personal preference. Unless you're a professional marksman in a competition, a cut-rifled barrel won't be necessary. The technology found in button rifling and cold-hammer forging has grown so much that any method of rifling and fabrication will likely give you MOA accuracy out to at least 100 meters (if you're good enough).

AR-15 Barrel Steels Explained

This is a fun topic because so many AR-15 owners and shooters have proudly (and wrongly) claimed so many things about AR-15 barrel steel. There are many misconceptions and myths about "mil-spec" steel, "chromoly vanadium" and the like. Let's talk about the types of steels that barrels are made of, then we'll dispel some of the crazy things you've probably read on forums like AR15.com or M4carbine.net.

4140 Chromoly

4140 Chromoly is a very common gun steel found in many AR-15 barrels. This steel contains a mixture of carbon, chromium, manganese, molybdenum, phosphorus, silicon, sulphur, and iron. The chromium and molybdenum are what give 4140 Chromoly its name. These barrels make excellent budget barrels and they'll afford most shooters exceptional accuracy at the range.

4150 Chromoly

4150 Chromoly is an upgraded version of 4140 Chromoly steel, and it contains 0.1% more carbon. This extra carbon content gives 4150 Chromoly slightly better properties for machining and fabrication. It also makes the steel slightly harder, providing longer barrel life and slightly better accuracy.

Chromoly Vanadium

This is the gold standard steel of AR-15 barrels. Chromoly Vanadium steel (commonly called "4150 CMV") includes 0.20 to 0.30% Vanadium in its alloy. This added material reduces the size of the crystalline structures in the steel, making it even tougher and harder. Many Colt carbine barrels (the ones found in O.G., troop-issued M4 rifles) are made from CMV.

416R Stainless

Shooters wanting the most accurate AR-15 barrel possible should stick with a 416R stainless barrel. This stainless steel boasts excellent machining and fabricating properties, it's incredibly resistant to heat and moisture, and it's a very hard, consistent, dense metal. Any barrel that's rifled from 416R stainless will typically afford sub-MOA accuracy. These barrels are usually the most expensive on the market.

The "Mil-Spec" Barrel Myth = Busted

Mil-spec vs. "non-mil-spec" barrels

A lot of shooters like to make assumptions about barrel steel and whether it's "mil-spec". Some argue that certain barrels are mil-spec because they have Vanadium in them, while others don't. Some have said that only 4150 steel or only CMV steel is considered mil-spec. Others say that there's a "special" type of barrel steel called 41V50, and that steel is the only one that's mil-spec.

All of these assumptions are wrong. Yes, we're looking at you, 30+ pages of posts and arguments on forums. Here's the truth: Any barrel made from 4150 or CMV steel is mil-spec. The military uses a certification process outlined in a document called MIL-B-11595E. That document details exactly what materials need to be present in a rifle barrel for it to be considered mil-spec:

Would you look at that? All 4150 and CMV barrel steels are considered mil-spec by the U.S. Military. You can also see that "41V50" isn't listed anywhere. It doesn't exist. If you want to shut down any other arguments about barrel steel and mil-spec certifications yourself, download the full version of MIL-B-11595E here. Then, happily share it and spread some truth.

Types of Barrel Treatments

Every barrel needs to be treated and coated with some sort of protective finish. Nearly all AR-15 barrels sport a matte black finish and some sort of treatment for the rifling inside. Even some stainless barrels have their rifling and exterior treated with an extra layer of protection. But there are many ways to achieve this look and protection. Let's break 'em all down:

Melonite/Nitride

You've probably seen these two phrases quite a lot, but they're one in the same. Melonite is just a branded name for the process of nitride-treating a barrel. A Melonite/nitride finish is technically a case-hardened finish. This finish is achieved by submerging the barrel in a "ferritic nitrocarburizing" salt bath. Basically, the barrel's heated to around 1,600 degrees and submerged in a liquid mixture of nitrogen, oxygen, and carbon. These elements are thus forced into the steel. These three elements bind and create a layer that bonds with the steel itself.

Once cured, a Melonite/nitride finish affords a Rockwell Hardness rating of 55 to 65. If you're not familiar, that is an incredibly hard rating. This gives the barrel superior life and accuracy. As a freshly nitride-treated barrel is first exposed to oxygen, it turns a dark, matte black color.

Manganese Phosphate ("Parkerized")

A manganese phosphate finish (sometimes called a Parkerized finish, which is a brand name) coats the barrel with a matte black texture, similar to a nitride treatment. The manganese element creates a dense, slight porous, crystalline structure atop the steel. This coating allows the metal to absorb oil and lubrication, and it seals the raw steel underneath from the elements.

A manganese phosphate finish also sports a high Rockwell Hardness rating, though it isn't as hard or protective as a nitride finish. Phosphate finishes are less expensive than nitride treatments and the process of applying them is easier. Most phosphate finishes are applied at around 176 degrees - a stark contrast to the conditions required for a nitride finish.

Chrome Lining

Chrome lining is a treatment applied to the inside of an AR-15 barrel. Chrome lining is essentially an alternative to a Melonite/nitride finish. During this process, chrome is applied to the lands and grooves of the barrel's rifling, as well as the chamber. In order to ensure accuracy with this extra material, chrome-lined barrels are typically bored out more than the final internal diameter. The tolerances are made up by adding the chrome to the inside of the bore.

Chrome lining was popular for many years. Advancements in nitride treatments have largely made chrome lining obsolete. Similar protection and performance can now be had in a Melonite/Nitride-treated barrel. Less expensive 4140 barrels are sometimes chrome-lined to make up for their lower hardness rating.

Conclusion

Whew, that was a lot of info to digest. We know there are endless factors to consider when buying your black rifle's barrel, but here's a quick recap of the big points and best practices:

- There is no "universal" twist rate for the standard AR-15.

- Most AR-15s chambered in 5.56 or .223 use a 1:7 or 1:8 twist rate.

- 300 Blackout favors 1:8, while the LR-308 works well with 1:10.

- Barrel length doesn't equal accuracy, velocity and twist rate does.

- Only buy a barrel that's long enough to maximize velocity before diminishing returns.

- Most barrels' rifling is formed by cold-hammer forging or by button rifling.

- 4140, 4150, CMV, and 416R stainless are the four most common barrel steels.

- Any barrel made of 4150 or CMV is considered mil-spec per MIL-B-11595E.

- Nitride and phosphate coatings are the most common barrel finishes.

- Chrome lining can also be applied to rifling to increase barrel life.

Got more questions about AR-15 barrels, how to build one, or something else related? Get in touch with us. We're happy to talk over the phone or through email. We've all built our own guns in our spare time and we're glad to be a source of information."

DISCLAIMER: If you are new to the world of DIY gun building, you likely have a lot of questions and rightfully so. It’s an area that has a lot of questions that, without the correct answers, could have some serious implications. At GunBuilders.com, we are by no means providing this content on our website to serve as legal advice or legal counsel. We encourage each and every builder to perform their own research around their respective State laws as well as educating themselves on the Federal laws. When performing your own research, please be sure that you are getting your information from a reliable source.